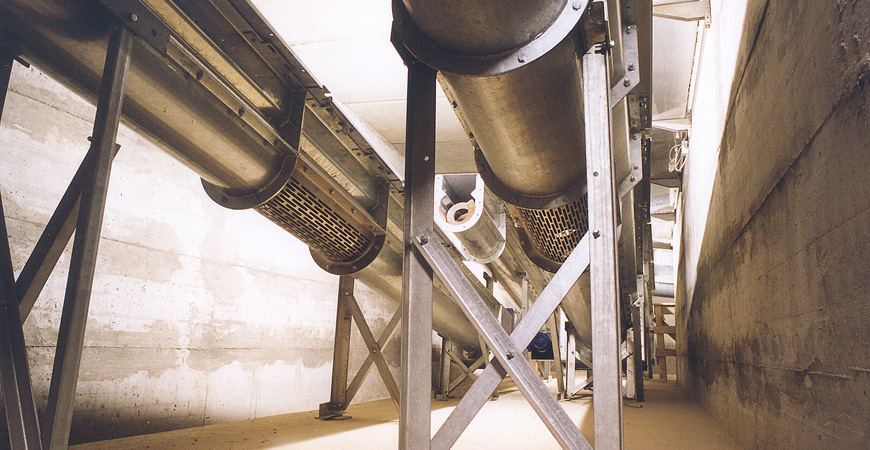

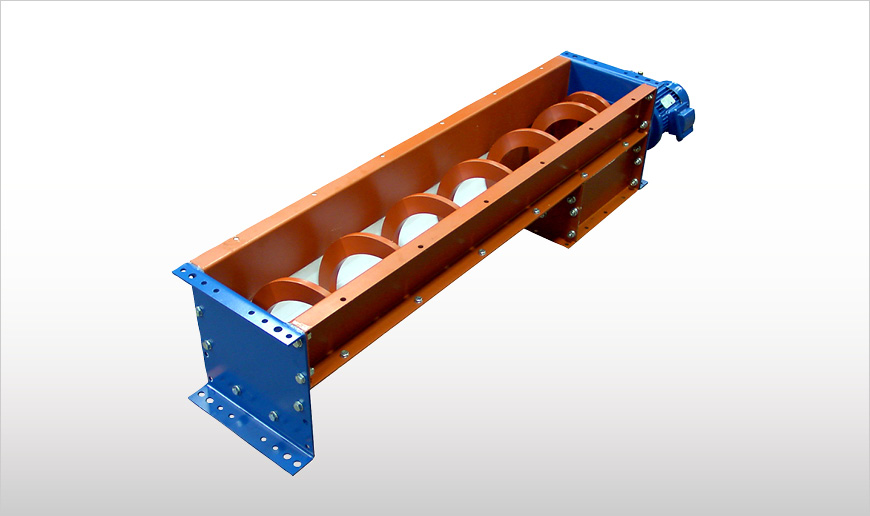

The Shaftless Screw offers a larger volume capacity and the capability of handling particularly difficult materials such as those that tend to become tangled up or those that present highly variable particle size. Construction material properties, oversize thickness, as well as a special manufacturing process make the spiral highly resistant and extremely durable. Due to the absence of intermediate bearings, obstacle-free material handling is guaranteed. The completely enclosed trough prevents any material leakage. Trough covers with appropriate gaskets enable odor-free operation and prevent contaminants from entering the system. At the same time the conveyor offers maximum access to the inside for inspection and cleaning. Maintenance is reduced to the minimum due to a small number of components. There is a vast choice of liners depending on the specific material characteristics.

SSC Shaftless Screw Conveyors have been specially designed for handling of difficult heterogeneous materials like urban solid waste, screenings and floating matter, de-watered, thickened, conditioned sludge, packaged food, waste from: meat, fish, fruit and vegetable processing. These screws have also been used successfully in dry abrasive products such as cement, sand, and abrasive dusts. The main sectors of application are wastewater treatment, sugar mill waste products, fish industry, solid waste treatment, fruit and vegetable processing plants, beverage industry, cement packaging, cement mills, dust collection, pulp and paper, chemical industry, food industry in general, meat processing plants, rendering plants, slaughterhouses, restaurants, canteens, catering in general.