Industrial Food Mixers

MAP extends its expertise into the domain of industrial food mixing, where precision and versatility are paramount. MAP equipment is adept at handling a vast spectrum of food products, from staple ingredients like flour to intricate dessert mixtures and spices. Whether it's freeze-dried sauces and soups or food supplements and meal replacements, MAP mixers ensure homogeneity and quality throughout the production process. The versatility of its machines is evident in their capability to blend diverse ingredients, ranging from vitamins and food colourants to sweeteners and energy drinks. From yeast and flavour enhancers to baby formula and cocoa, from tabbouleh to cornflakes and chocolate bar mixtures, MAP's industrial food mixing equipment is the cornerstone of efficiency and excellence in the food manufacturing industry.

Industrial Mixers for Spices

Our expertise in spice mixing ensures properties and characteristics are preserved without damaging granules. We can increase productivity by mixing recipes in as little as 30 seconds. Our machines, designed for high fill levels and low installed power, are efficient and cost-effective. At MAP, we prevent granule damage and minimise heat generation protecting sensitive ingredients. We specialise in preserving spice freshness, injecting, and homogenising flavours, essential oils, and preservatives at the end of the mixing cycle. Our technology maintains the “spiciness” of specific spices, ensuring a high-quality final product.

Industrial Mixers for Salt Processing

Industrial Mixers for Sugar Processing

Avoiding the dispersion of fine sugar powder and preventing granule breakage or ensuring controlled granulation is essential. Reducing mixing times without overheating the product is a priority. MAP provides solutions for these needs. Our machines address issues with product heating during mixing and are suitable for installation in explosive environments. When changing recipes, our advanced mixing solutions prevent contamination and maintain product integrity. We also offer effective homogenisation of colourants and additives, preventing product agglomeration and clumping. At MAP, we enhance efficiency and reliability in your operations, ensuring product integrity.

Industrial Mixers for Flour Processing

Industrial Mixers for Ice Cream Powder Processing

Industrial Mixers and Blenders for Instant Drinks Processing

Industrial Mixers for Processing of Flavourings, Vitamins and Others

We protect sensitive ingredients like flavours, vitamins, and additives with encapsulation for stability. Our solutions ensure efficient processing, emulsification, optimal absorption, and gentle mixing. We denature proteins, deactivate enzymes, and offer flexible vacuum heating and cooling.

Industrial Mixers for Processing of Cocoa Powder and Chocolate Additives

Industrial Mixers for Breakfast Cereals Processing

We provide solutions for managing product variability and recipe flexibility with high productivity. Our systems ensure quick recipe changes, gentle ingredient handling, precise additions, temperature control, and integrated processes like mixing, coating, and drying, preserving product quality.

Industrial Mixers for Biscuits (Cookies) Processing

Industrial Mixers for Baby Food Processing

REFERENCES FOR FOOD MIXERS

Related Mixing Machines

BATCH MIXERS

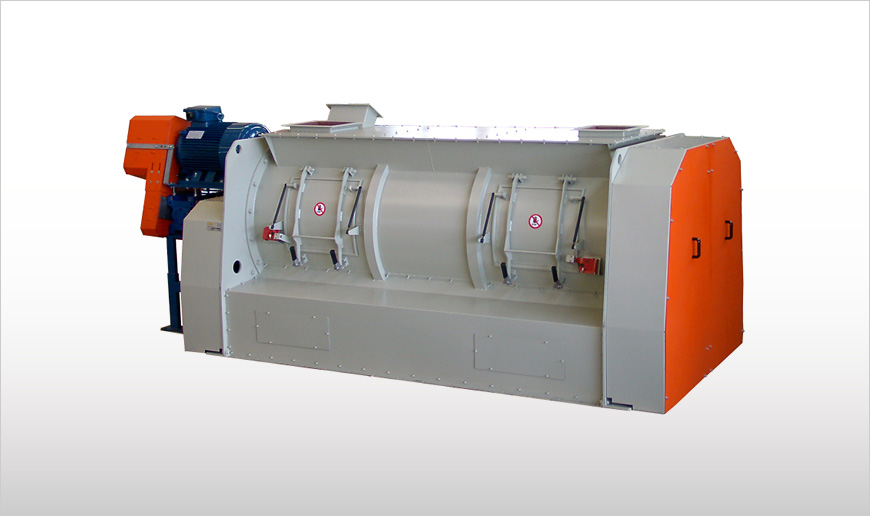

Batch-Type Single Shaft Industrial Mixers WBH

The WBH Batch-Type Single Shaft Industrial Mixer is the ideal machine to obtain highest quality mixtures in perfectly reproducible batches. In the last three decades MAP has supplied thousands of mixers to a large variety of industries worldwide. Mixing tests for customers are performed in the Group’s own laboratories in currently more than fifteen countries.

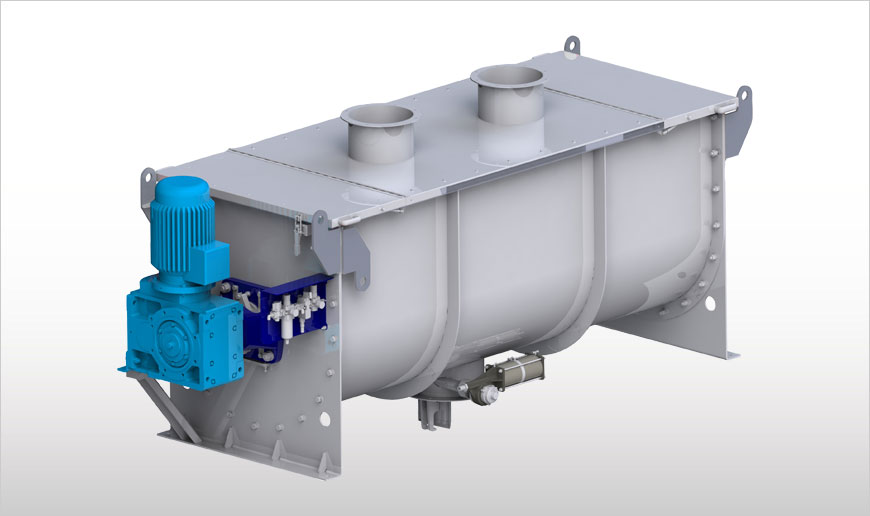

Read moreBatch-Type Single Shaft Industrial Mixers with Bomb-Bay Discharge WBHP - WBHT

In addition to the features of standard WBH industrial mixers, the WBHP and WBHT-type ensure instant product discharge with residue of less than 0.1% depending on the product mixed. A bomb-bay discharge is mandatory where discharge time has to be reduced to the minimum.

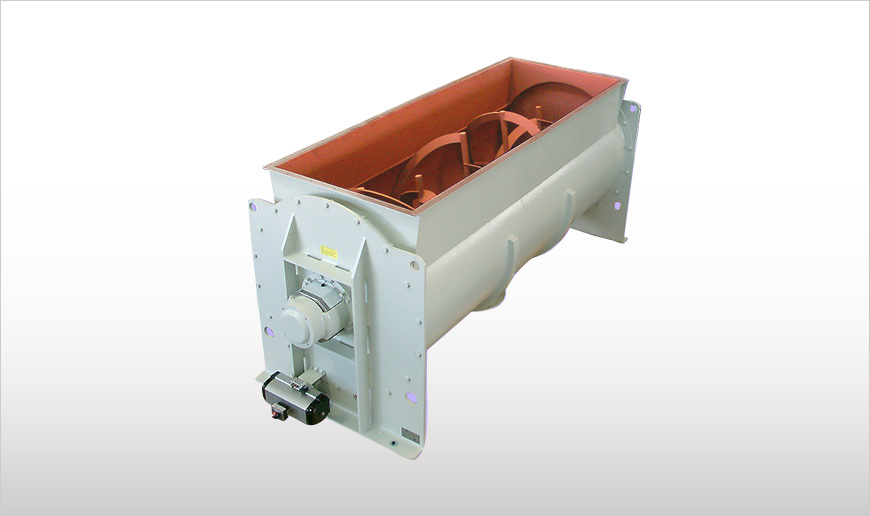

Tubular Batch-Type Industrial Ribbon Blenders WBN

The WBN Batch-Type Industrial Ribbon Blender, with its slowly turning single shaft double counter-pitch ribbon screw, is the ideal machine to obtain high quality mixtures with fragile materials, at the same time conserving the physical properties of the product.

Single-Shaft Industrial Ribbon Blenders WBR

WBR Industrial Ribbon Blenders are the ideal solution to meet the requirements of the market in terms of quality, maintenance and mixing technology. Thanks to the use of proven standard components, MAP® is able to offer an attractive price without compromising on quality.

Read moreCONTINUOUS MIXERS

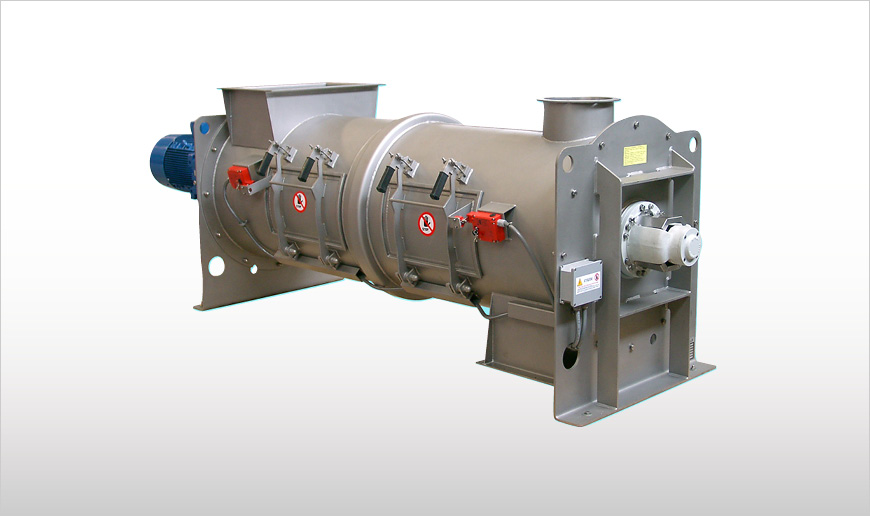

Continuous Single Shaft Industrial Mixers WAH

The WAH Continuous Single Shaft Industrial Mixer is the ideal machine to obtain highest quality mixtures. Mixing with WAH is quick though gentle. Thousands of mixers supplied in the last three decades by MAP all over the world stand for total reliability and durability.

Read moreLaboratory Mixers

Laboratory Industrial Mixers MLH

The MLH is a highly efficient, extremely versatile laboratory industrial mixer. In research institutes as well as

in the test facilities of various industries, the MLH mixer offers extensive possibilities for testing

process feasibility. In addition, it is ideally suited for small scale production.