PLASTIC PROCESSING AND RAW MATERIAL

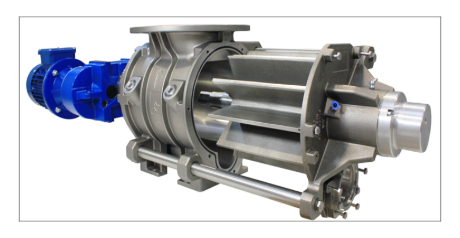

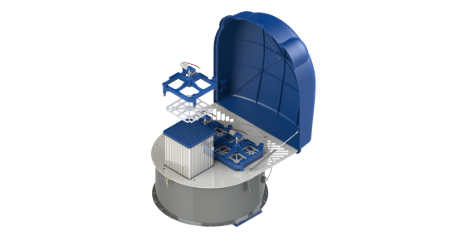

As a result of decades of experience in mixing technology, MAP offers industrial mixers specifically developed for the chemical industry. Confident collaboration with leading international companies and excellent local manufacturers has greatly contributed to the definition of a quality standard specifically for chemical applications. Experience, advanced technical solutions and the careful hygienic design of the machines have enabled MAP to achieve these results. Multifunctionality is one of our hallmarks: thanks to the MAP design, accessories and options, several processes can be carried out with one machine. This makes it possible to avoid premixing or separate thermal systems.

Products manufactured on MAP mixers in the chemical industry

Industrial Mixers for Processing of Fertiliser, Pesticides, Agricultural Solvents, Plant Care

Our expertise lies in rapid mixing techniques that preserve granule integrity, ensuring no breakage during processing. We achieve uniform granulation with binding liquids for enhanced dispersion and improved product performance in application. Our machines handle diverse bulk densities and granule sizes, enabling successful blending without compromising quality. We compact granules for safe transport and storage, ensuring they retain their properties. Additionally, our solutions minimise dust formation, promoting a clean, safe working environment. Our advanced mixing technologies address key challenges in granulation and product integrity, delivering efficient processes with consistently high quality.

Industrial Mixers for Processing of Brake Pad Friction Linings

We provide durable, cost-effective solutions to tackle abrasion and corrosion in production processes. Our mixers are engineered to withstand wear, ensuring reliability and longevity in demanding environments. With built-in temperature control, our machines can effectively cool or heat products, preserving ingredient quality and integrity throughout production. This feature enables optimal processing conditions, precisely tailored to specific requirements.

Industrial Mixers for Processing of Detergents, Soaps, Toothpastes, Cleaning Agents

We create and homogenise granules for rapid dissolution in applications, ensuring high solubility and enhanced product effectiveness. Our compaction techniques preserve granule properties during transport and storage, guaranteeing products reach their destination intact and ready for use. By minimising dust, we promote a clean environment and safe handling throughout production. Advanced choppers prevent clumping, delivering smooth and consistent granulation. Our machines enable quick mixing without heat damage, preserving product integrity. Consolidating multiple functions, our mixers de-agglomerate, granulate, dry, and coat in a single unit, streamlining operations and boosting efficiency.

Further products manufactured on MAP mixers in the chemical industry

Industrial Mixers for Processing of Crushed Raw Materials

Raw material crushing, Granulating powders with liquid components, Fertiliser, NPK ternary fertilisers, Agricultural soil amendment, Explosives, Ammonium nitrate and fuel oil, Petrochemical plastics, Laundry detergents, Fine chemicals, Antimony + resin.

Industrial Mixers for Processing of Various Dry Powder Mixtures

Dry powder mixtures, Fibres or granules, Active agents or catalysts, Organic or inorganic colour pigments, Battery materials, Fertiliser, Fire extinguisher powders, Pesticides (fungicides, herbicides, insecticides), Separating agents, Detergents, Blasting agents, Cellulose, Soil conditioners.

Industrial Mixers for Processing of Detergents, Wood, Ligno Substances, Resins

We specialise in creating granules for rapid dissolution, ensuring effective product performance. Our compacting methods maintain granule integrity during transport and storage, reducing waste and enhancing efficiency. We minimise dust for a safer, cleaner workspace and eliminate clumping for consistent quality. Our mixers enable rapid, heat-free mixing, consolidating multiple processes into one efficient unit.

Our values are the reason we make the same choice every day

That's why choose WAM®AIR

CONTACT US

.png?sfvrsn=55821d43_2)

-(custom).jpg?sfvrsn=bb0d16ed_2)