Technology-driven In-house Filter Manufacturing

Since 1991, WAM®AIR has been manufacturing in-house engineering polymer components, advancing Dust Filtration technology with precision and expertise.

Machine tools are the backbone of modern manufacturing. To meet the demands of the Smart Factory, WAM®AIR leverages state-of-the-art internal metalworking solutions. Through automation and cutting-edge technology, we have optimised quality management, ensuring exceptional precision, attention to detail, and superior finishing that set us apart.

State-of-the-Art Labs for Advanced Filtration Research and Performance Enhancement as well as cutting-edge industrial series production.

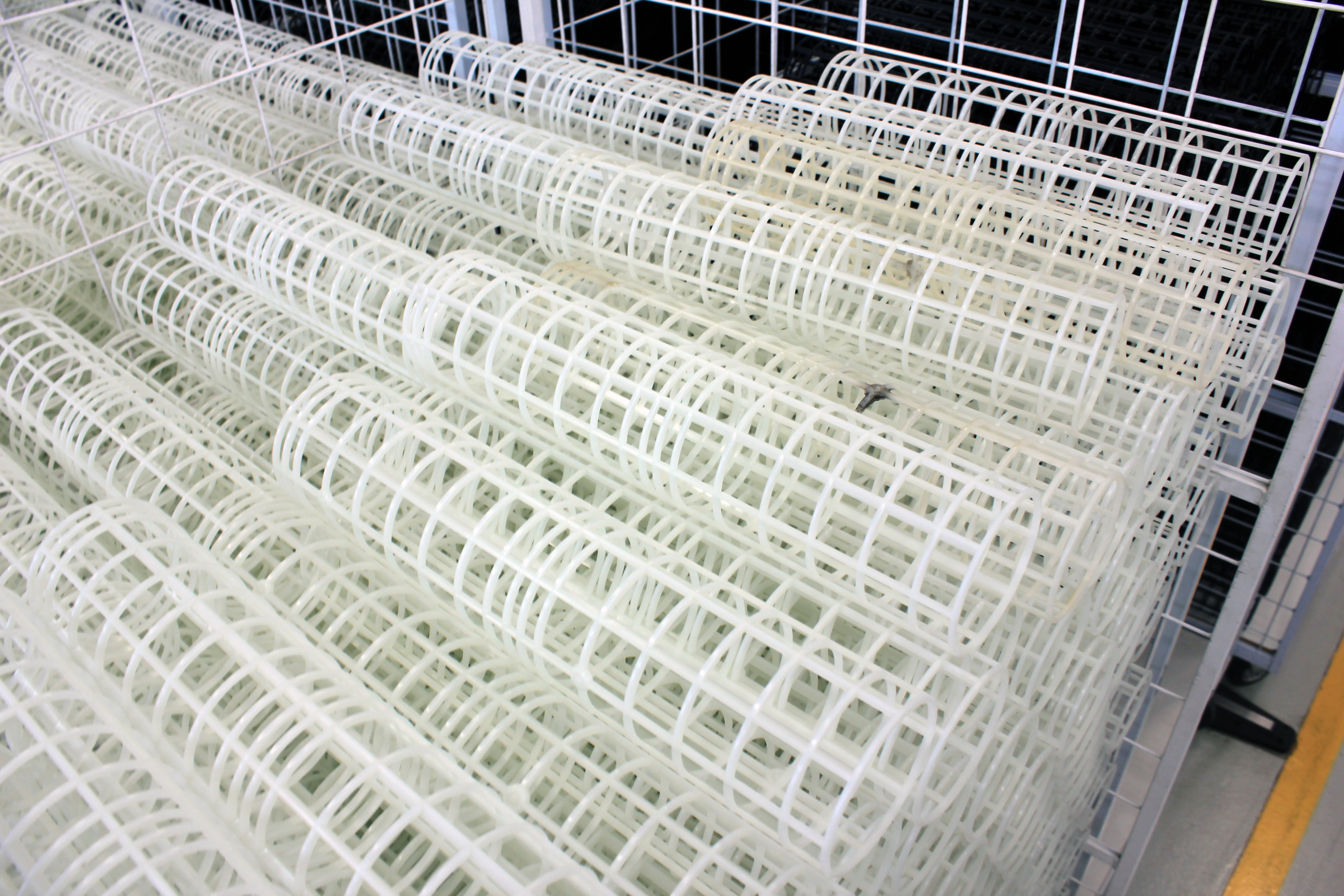

Nanofibre electro-spinning line in cleanroom

WAM®AIR advances nano-fibre production with cutting-edge electrospinning technology, enabling precise, scalable processing for industrial dust filtration applications. The equipment ensures consistent fibre morphology, uniformity, and high throughput. By integrating automation and stringent quality control, WAM®AIR sets a benchmark in nano-technology, driving innovation and reliability in next-generation material manufacturing.

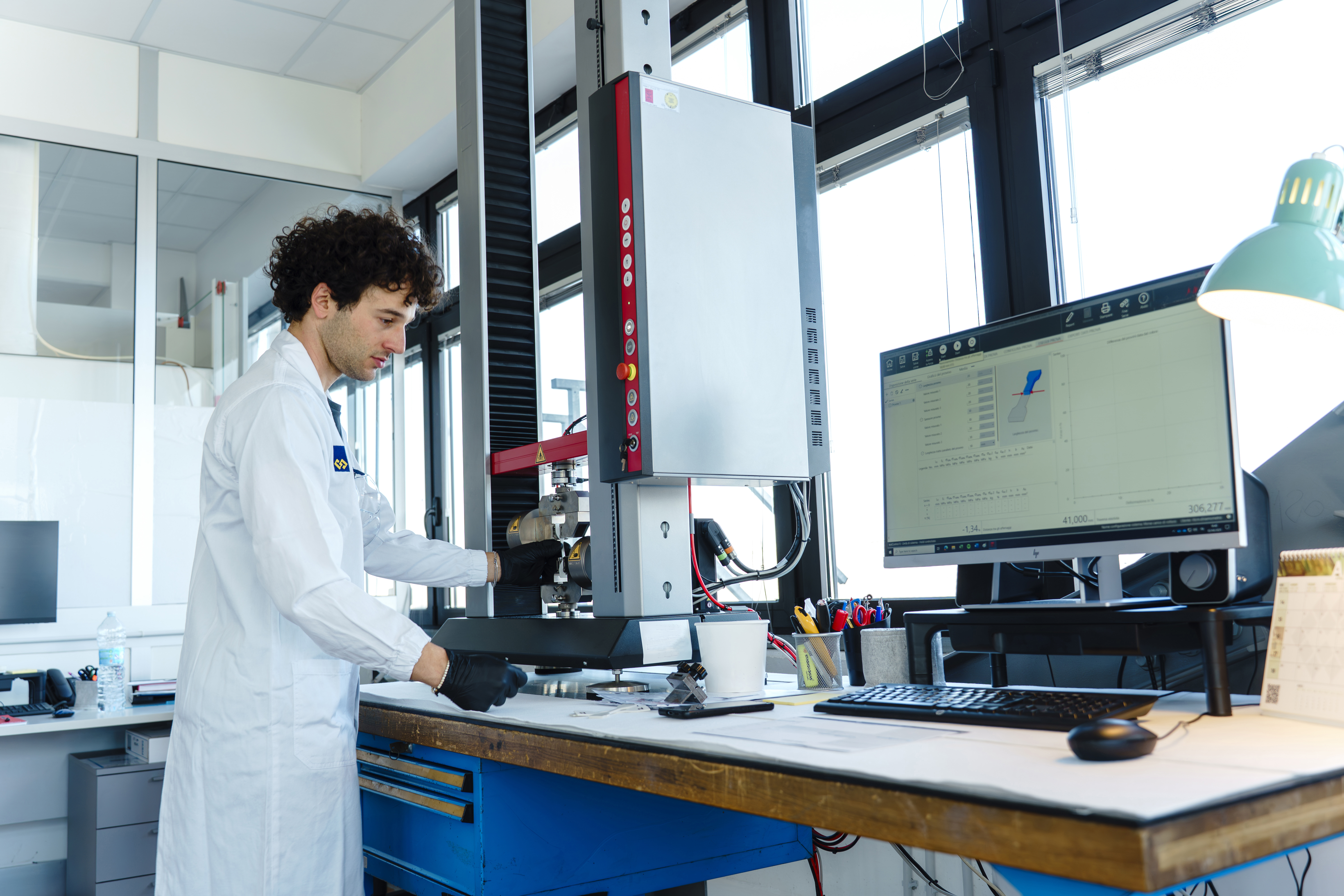

Tensile strength tests for engineering polymer materials

Tensile strength tests on engineering polymers assess their resistance to breaking under tension. These evaluations are vital for determining material performance in structural applications, guiding design choices in automotive, aerospace, and construction industries. Accurate testing ensures reliability, safety, and compliance with international engineering standards.

Chemical and technological laboratory

Basic chemical lab tests, including spectroscopy, thermal analysis, and solubility assessments, are essential in developing new engineering polymer formulas. These tests help identify molecular structure, stability, and compatibility, ensuring formulations meet required performance criteria for a variety of industrial applications.

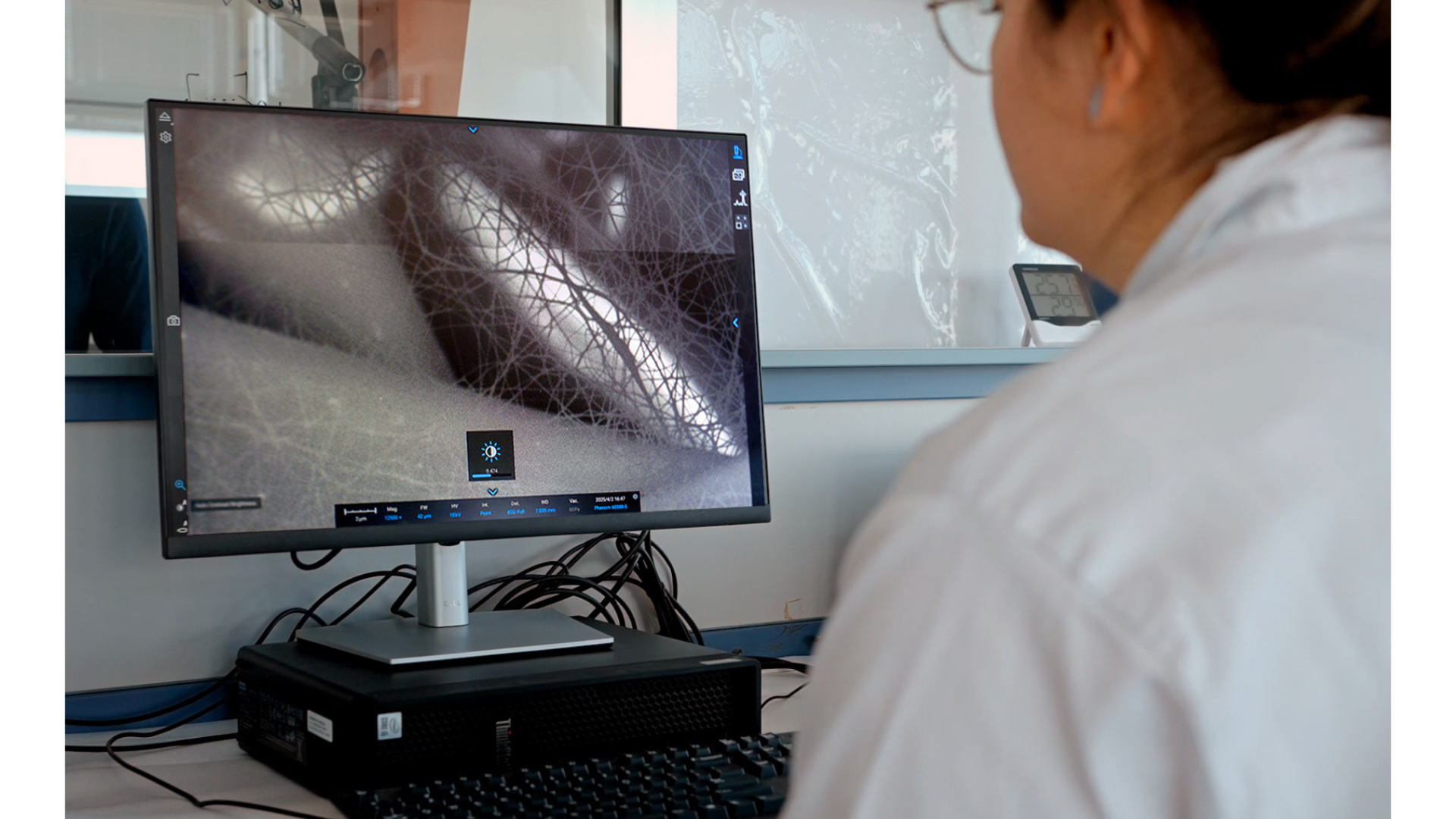

Filter performance testing in-house laboratory

The WAM®AIR test lab employs a scanning electron microscope (SEM) to deliver high-resolution imaging of filter media. This advanced tool enables precise analysis of particle capture and surface morphology, ensuring rigorous quality control and innovation in air filtration technology.

Wind tunnel

WAMGROUP’s R&D department has developed a state-of-the-art wind tunnel to test dust filter elements under controlled conditions. This facility enables precise analysis of airflow dynamics and filtration efficiency, supporting product innovation and compliance. The initiative underscores WAMGROUP’s commitment to advancing environmental performance and operational reliability in dust filtration technologies.

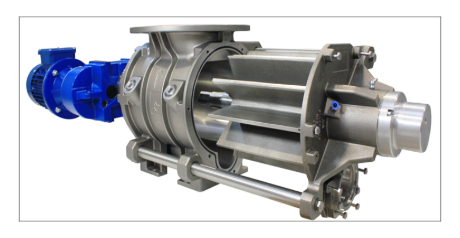

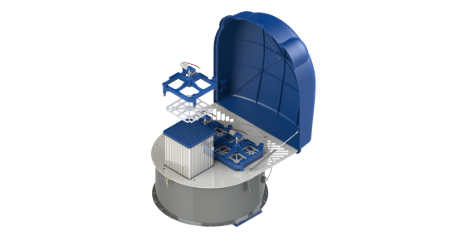

Casing assembly in industrial series production

WAM®AIR operates advanced dust collector production facilities in Italy and internationally, combining automated manufacturing with rigorous quality control. These sites ensure high-volume output and consistent standards across markets. Leveraging cutting-edge technology and global expertise, WAM®AIR reinforces its position as a leading provider of efficient, reliable dust collection solutions worldwide.

Robot-supported, automated component production

WAM®AIR has implemented robot-supported, automated manufacturing for filter elements, enhancing precision, consistency, and production speed. This technological shift reduces human error and boosts efficiency, ensuring high-quality output at scale. The move reflects WAM®AIR’s ongoing investment in Industry 4.0, setting new standards in filter technology and industrial automation.

In-house engineering polymer component development and production

Since the early 1990s, WAMGROUP has pioneered the use of engineering polymer components in its equipment, enhancing durability, reducing weight, and improving corrosion resistance. This strategic innovation marked a turning point in industrial machinery design, reinforcing WAMGROUP’s reputation for forward-thinking engineering and long-term commitment to materials science advancement.

High-quality finishing

WAM®AIR ensures high-quality finishing of stainless-steel casings for its dust collectors through precision engineering and advanced surface treatment techniques. The result is enhanced corrosion resistance, aesthetic appeal, and long-term durability. This meticulous attention to detail reflects the company’s dedication to excellence in both performance and presentation of its products.

Worldwide delocalised equipment assembly

WAM®AIR manufactures dust collectors across four continents, ensuring global availability and localised support. By integrating uniform quality standards with region-specific expertise, the company delivers consistent, high-performance solutions worldwide. This expansive footprint underscores WAM®AIR’s commitment to responsive service, supply chain resilience, and leadership in industrial dust filtration on a global scale.

Our values are the reason we make the same choice every day

That's why choose WAM®AIR

CONTACT US

.jpg?sfvrsn=d166e1d4_1&size=1920)

.png?sfvrsn=55821d43_2)

-(custom).jpg?sfvrsn=bb0d16ed_2)