WAM®AIR Plus - Understanding the Customer’s Needs

“For a dust-free future”

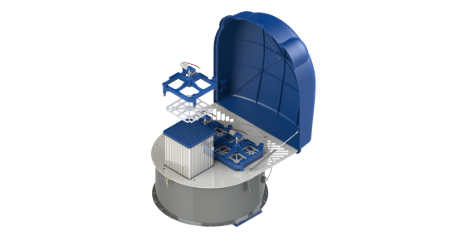

Choosing the right Dust Collector is essential for ensuring a plant complies with air emission regulations. It must efficiently direct dust-laden air through the Filter Medium, capturing particles on its surface to maximise both performance and lifespan.

Key factors for optimal Dust Filter Performance:

Filter Element

Filter Medium

Filtration Velocity or “Air-to-Cloth Ratio”

Sustainability

Saving energy, time, space, and money while protecting the environment and enhancing safety. Our cutting-edge dust removal technology operates without compressed air (LCA analysis) for maximum efficiency. Designed for superior fine particle filtration, it meets ePM ISO 16890 standards, ensuring cleaner air and sustainable industrial performance.

Detailed information on WAMGROUP®'s efforts and activities in the area of sustainability you can find at www.wamgroup.com.

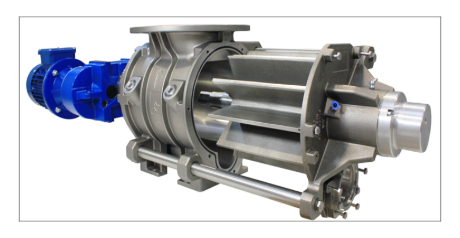

Technology-driven in-house filter manufacturing

Since 1991, WAM®AIR has been manufacturing in-house engineering polymer components, advancing Dust Filtration technology with precision and expertise.

Today, the WAM®AIR Division sets an international benchmark for production depth.

INNOVATION

INNOVATION drives us, PERFORMANCE defines us.

- 50 years of expertise with over half a million dust collectors installed worldwide.

- In-house, technology-driven manufacturing

- State-of-the-art labs for advanced filtration

SUSTAINABILITY

SUSTAINABILITY, Energy, Frequency and Vibration:

- Saving energy, time, space, and money while enhancing safety and respecting the environment

- Cutting-edge dust removal with NO COMPRESSED AIR (LCA analysis)

- High-efficiency fine particle filtration (ePM ISO16890)

GLOBAL PRESENCE

Our values are the reason we make the same choice every day

That's why choose WAM®AIR

CONTACT US

.png?sfvrsn=aac47b09_1)

.png?sfvrsn=55821d43_2)

-(custom).jpg?sfvrsn=bb0d16ed_2)